In the Northeast end of the Markt in Gouda is the Waag, a seventeenth-century building that was the cheese-weighing house and is now a museum dedicated to Dutch cheese.

Just over the front door is a relief of cheese weighing in action. This sculpture is a copy of the original which is now stored inside, where it shows its signs of weathering.

The ground floor of the building is a combination tourist center, shop, and a slice of the museum.

Visitors pay a modest fee to go upstairs for the rest of the museum. The friends who came with us were mistaken for relatives and we paid the family rate for everyone.

The first floor had exhibits about Gouda specifically and that's where the original bas relief is found.

Up another flight of stairs is the exhibit on cheese making, which includes a video in Dutch with English subtitles. J and L loved watching the video which let us examine the cheese-making items in the room.

The process starts with cows though historically experts think that the first cheeses were made by accident. Ancient man stored milk in sacks make from calves' stomachs. As the milk sloshed around, the enzymes still in the stomach caused the milk to separate into a liquid and a white mass. The mass was taken out and then pressed to get additional liquid out, forming the first cheese. Cheese was (and is) handy since it is edible much longer than the milk from which it is made. The museum display continues on with the Dutch methods.

With the milk, the next step is to mix it with rennet (based on the enzymes from the cow, though rennets have been developed from other sources for vegetarians), which will thicken the milk and separate out the whey (the liquid part). Also, lactic acid is added to help the rennet, to provide flavor, and to kill bad bacteria.

The next step is to remove more whey by putting the cheese in molds and pressing.

After pressing, the cheese is cured in salt water. The salt helps to provide flavor and makes it stay fresh longer. A cheese mark may be added at this point to identify who made the cheese and where.

The cheese is then aged. Young cheeses are mild and creamy while older cheeses are more flavorful and drier. The maturing process can go from one month to one year or more. Once it's ready for sale, a label is attached and it's off to market!

The Netherlands is an ideal area for cheese-making, since the low, moist lands provide excellent grazing for dairy cows. Farmers would often make cheese and then bring it to market day to sell along with their other produce. The Gouda city council was granted the right to tax cheese in 1667. They built the Waag in 1668 to weigh the cheese and determine how much tax should be paid.

The exhibit has a small display on butter making as well, though that was of much less interest to everyone.

After the second watching of the video, the kids went around admiring everything. They were done in about two minutes, so it was lucky for us that we had more time!

We also noted the industrial, table-mounted cheese grater.

Soon enough we went back down all the stairs and bought some samples to take back to England. Truth be told, we ate a bunch of it on the way back to England.

|

| Kaaswaag, Gouda |

|

| Back of the Kaaswaag |

Just over the front door is a relief of cheese weighing in action. This sculpture is a copy of the original which is now stored inside, where it shows its signs of weathering.

|

| Bas relief of cheese weighing |

|

| Original inside the museum |

The ground floor of the building is a combination tourist center, shop, and a slice of the museum.

|

| The shop |

|

| Cheese weighing and stained glass! |

|

| Cheese and a Dutch girl |

|

| Cheese press with L's cheesy smile |

Visitors pay a modest fee to go upstairs for the rest of the museum. The friends who came with us were mistaken for relatives and we paid the family rate for everyone.

The first floor had exhibits about Gouda specifically and that's where the original bas relief is found.

|

| Ye olde mappe of Gouda |

Up another flight of stairs is the exhibit on cheese making, which includes a video in Dutch with English subtitles. J and L loved watching the video which let us examine the cheese-making items in the room.

|

| Standard cheese-making equipment |

|

| Standard cheese-consuming equipment |

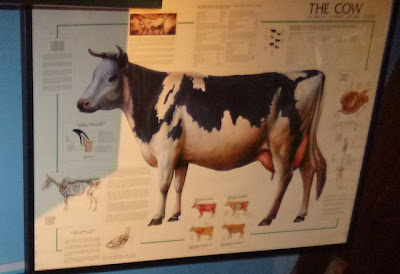

The process starts with cows though historically experts think that the first cheeses were made by accident. Ancient man stored milk in sacks make from calves' stomachs. As the milk sloshed around, the enzymes still in the stomach caused the milk to separate into a liquid and a white mass. The mass was taken out and then pressed to get additional liquid out, forming the first cheese. Cheese was (and is) handy since it is edible much longer than the milk from which it is made. The museum display continues on with the Dutch methods.

|

| The first step is to have the right shoes! |

|

| Anatomy of a cow |

|

| Tools for milking |

With the milk, the next step is to mix it with rennet (based on the enzymes from the cow, though rennets have been developed from other sources for vegetarians), which will thicken the milk and separate out the whey (the liquid part). Also, lactic acid is added to help the rennet, to provide flavor, and to kill bad bacteria.

|

| Mixing tools |

The next step is to remove more whey by putting the cheese in molds and pressing.

|

| Cheese presses and molds |

After pressing, the cheese is cured in salt water. The salt helps to provide flavor and makes it stay fresh longer. A cheese mark may be added at this point to identify who made the cheese and where.

|

| Pressed and cured, now for the aging process |

The cheese is then aged. Young cheeses are mild and creamy while older cheeses are more flavorful and drier. The maturing process can go from one month to one year or more. Once it's ready for sale, a label is attached and it's off to market!

|

| Many different local cheese labels |

The Netherlands is an ideal area for cheese-making, since the low, moist lands provide excellent grazing for dairy cows. Farmers would often make cheese and then bring it to market day to sell along with their other produce. The Gouda city council was granted the right to tax cheese in 1667. They built the Waag in 1668 to weigh the cheese and determine how much tax should be paid.

|

| More cheese-weighing equipment |

The exhibit has a small display on butter making as well, though that was of much less interest to everyone.

|

| Butter-making tools |

After the second watching of the video, the kids went around admiring everything. They were done in about two minutes, so it was lucky for us that we had more time!

|

| J ready to eat! |

We also noted the industrial, table-mounted cheese grater.

|

| This would be convenient |

Soon enough we went back down all the stairs and bought some samples to take back to England. Truth be told, we ate a bunch of it on the way back to England.

No comments:

Post a Comment